A tiny quartz crystal oscillator holds the lifeline of modern electronic systems. Failures such as resonant frequency deviation, oscillation stop, or signal jitter in quartz crystal oscillators can directly lead to typical malfunction patterns in electronic products, including timing disorder, communication failure, functional abnormalities, and startup issues.

As the frequency reference source for electronic systems, the performance of quartz crystal oscillators has become deeply integrated into product reliability design systems. From clock management in consumer electronics to synchronization systems in industrial control, their frequency stability and long-term reliability—measured by PPM-level precision—quietly define the user experience boundaries of modern electronic products.

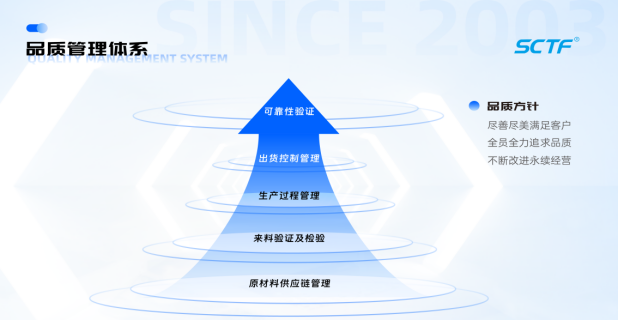

As an established brand in the quartz crystal oscillator field, SCTF Starcom Time & Frequency has maintained its industry positioning as the "Guardian of Frequency Standards" for 22 years. Backed by international quality certifications such as ISO 9001:2015 and IATF 16949, SCTF has built a full-lifecycle quality management system covering R&D, supply chain, manufacturing, and testing. This system not only embodies the company's technical expertise and smart manufacturing capabilities but also establishes a "zero-defect" standard as a moat for the reliability development of the electronics industry.

Let's delve into SCTF Starcom Time & Frequency's comprehensive quality management system to decode how 22 years of industry experience have refined quartz crystal oscillators to PPM-level precision through five core control dimensions:

1. Raw Material Supply Chain Management

2. Incoming Material Verification and Inspection

3. Production Process Management

4. Outgoing Quality Control

5. Reliability Validation

From stringent supplier assessments to extreme environmental testing, witness how this veteran brand instills frequency reliability into electronic products through full-chain precision control.

1. Raw Material Supply Chain Management

SCTF implements an ISO 9001-certified supply chain management system to strictly control raw material quality. A three-tier evaluation mechanism is adopted:

Qualification Review: Comprehensive audits of key suppliers (e.g., crystal blanks, bases, ICs) for technical capabilities and production scale.

Performance Testing: All raw materials undergo validations for appearance, electrical parameters, temperature characteristics, and reliability.

Dynamic Management: An Approved Vendor List (AVL) is maintained, with regular audits to monitor supply stability and batch consistency.

2. Incoming Material Verification and Inspection

SCTF enforces rigorous incoming inspection for each batch, testing chemical and physical properties to ensure only qualified materials enter production, eliminating quality risks at the source.

3. Production Process Management

SCTF operates in a Class 10,000 cleanroom with a 6S management system. A three-tier quality inspection process is implemented:

IQC (Incoming Quality Control): Ensures raw material compliance before production.

IPQC (In-Process Quality Control): Real-time checkpoints across 12 critical processes, including crystal cleaning, silver plating, and bonding.

FQC (Final Quality Control): 100% full-function testing before storage.

4. Outgoing Quality Control

Strict outgoing quality checks are performed:

OQC: Sampling inspections per GB/T 2828.1-2012 standards; only qualified batches are shipped.

5. Reliability Validation

SCTF's full-lifecycle reliability validation includes extreme tests:

Temperature cycling (-40°C to +125°C), humidity, salt spray (96h)

Reflow soldering (270°C peak), hermeticity (helium leak rate ≤3×10^-9 Pa·m3/s), solderability

Drop, vibration, acceleration, and aging tests

Through these rigorous measures, SCTF guarantees an end-user failure rate of ≤100 PPM, ensuring product reliability.

Adhering to its philosophy—"Perfectly satisfying customers, wholeheartedly pursuing quality, continuously improving for sustainable operation"—SCTF infuses craftsmanship into every step from raw materials to finished products. This relentless pursuit of precision has made SCTF's products the trusted "electronic heart" in 5G communications, AI robotics, industrial control, smart grids, new energy, and smart home applications, safeguarding the pulse of modern technology with stable frequencies.